Quality

Newonics has been ISO 9000/9001 certified since 2003. Copies of our quality manual are available for review at any time at the request of the customer.

Products manufactured at Newonics pass through 3 inspection points.

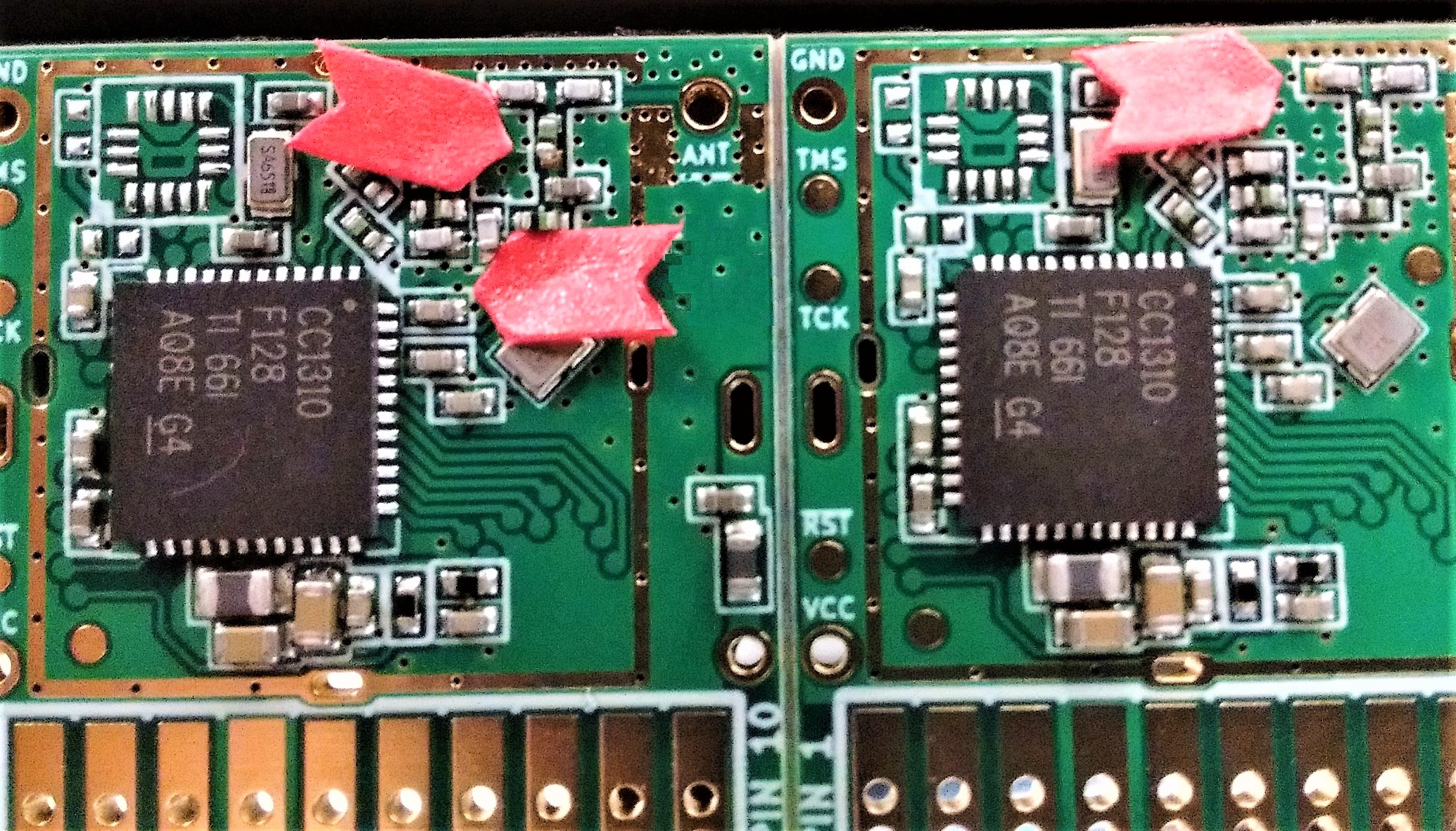

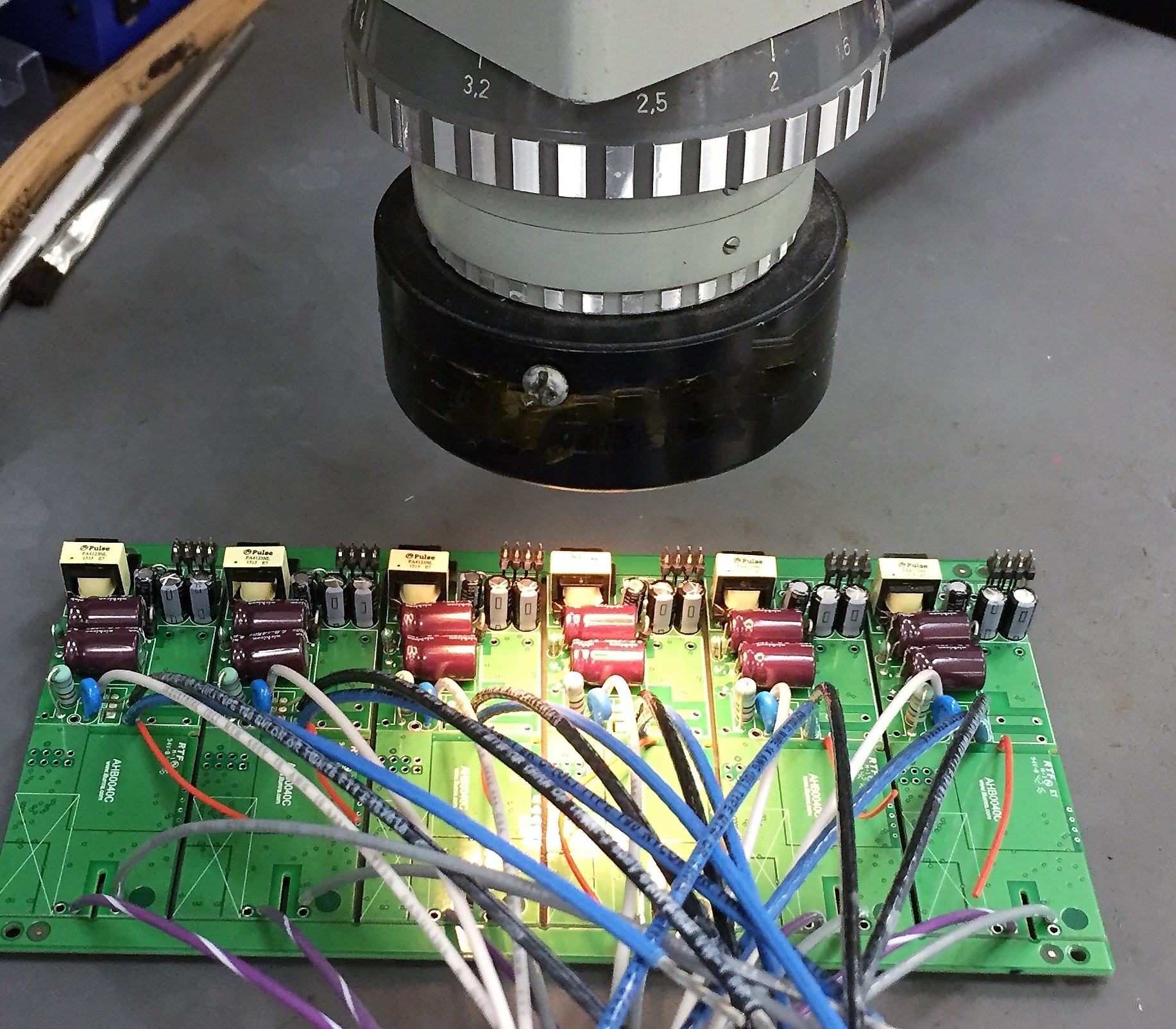

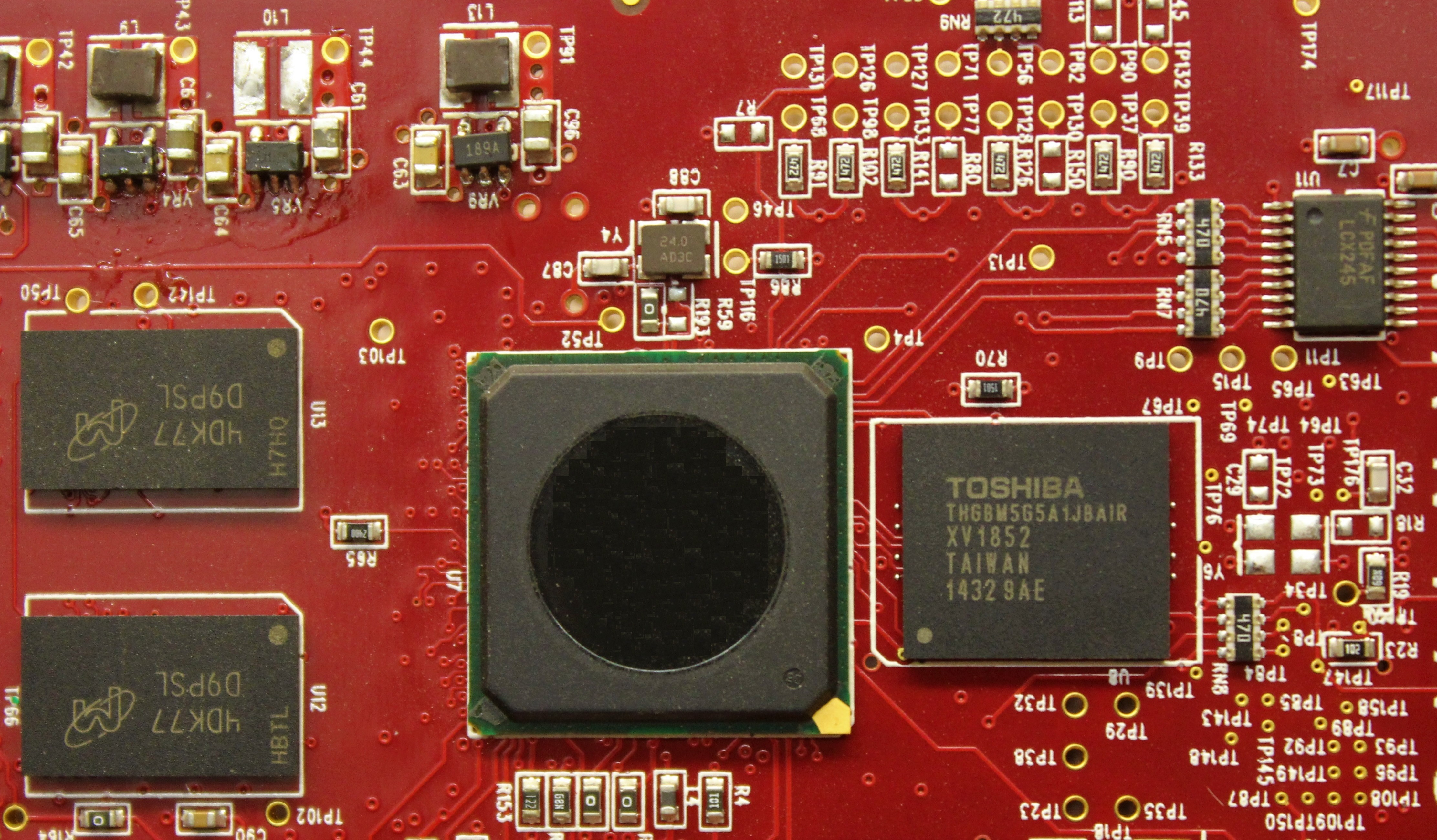

SMT Inspection – 100% of all PCB boards coming off our SMT lines pass through AOI inspection. Additional 100% visual inspection is then performed on components that are difficult to inspect with AOI (e.g. J-Leaded components). X-Ray and Endoscope inspection is used for BGAs and lead-free components.

Stuffing/Touch up Inspection – 100% visual inspection is performed on all thru-hole and hand soldered components.

OBQ – A final inspection is performed prior to shipment. OBQ (Out of Box Quality) inspection looks at any process performed after touch up and verifies inspection marks are present for prior inspection points.

Newonics follows strict document control procedures to insure the proper documents and work instructions are used during production.

Standards

All of our assemblies are built to meet IPC-A-610 standards. Newonics has the capability to meet Class 3 requirements but our standard is to build to Class 2 requirements. Newonics has the tools, experience and process to build your products to meet the RoHS Directive Directive 2011/65/EU. Currently registered to the ISO9001:2015 standard.

| Download ISO CERT |